Service Hotline:86-0592-5681408 / 86-17346269651

In the world of material handling, the forklift mast plays a pivotal role in determining how efficiently and safely loads can be lifted, lowered, and positioned. For anyone operating a forklift truck—whether in a warehouse, a factory, or a distribution center—understanding what is a forklift mast and how to choose the right one is essential.

What is a Forklift Mast?

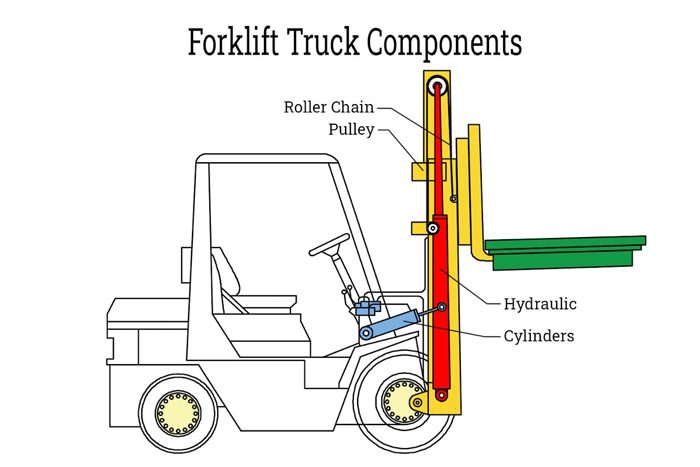

The forklift mast is the vertical assembly located at the front of a forklift truck that raises and lowers the load. It contains the hydraulic cylinders, chains, and rails that guide the movement of the carriage and forks. This mechanism is vital to the core function of all forklifts, especially in fast-paced logistics environments.

Common Types of Forklift Masts

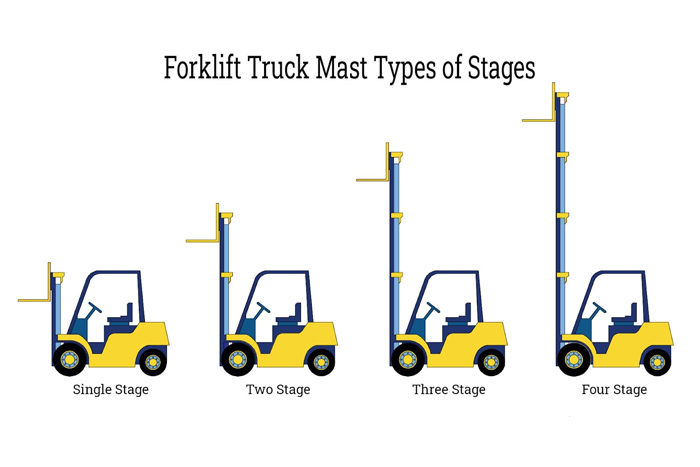

There are several mast configurations available, depending on the lifting requirements and working conditions. The most common include:

1. Single-Stage Mast (Simplex)

Design: One set of fixed rails, offering limited lift height.

Ideal for: Open outdoor use or where overhead clearance is ample.

Common in: Basic warehouse forklift applications.

2. Two-Stage Mast (Duplex)

Design: Two sets of rails for moderate lift capabilities.

Use Case: Well-suited for standard forklift trucks operating in warehouses or loading docks.

Balance: Provides good visibility and height performance.

3. Three-Stage Mast (Triplex)

Design: Three sections with hydraulic free-lift capabilities.

Application: Popular in high-rack storage or container loading environments.

Advantage: Often considered the best forklift mast type for flexible indoor/outdoor use.

4. Four-Stage Mast (Quad)

Design: Four interlocking sections for extra-high lift.

Use Case: Specialized lifting in very tall racking systems.

Note: Stability and visibility may be trade-offs at full height.

Height Options for Forklift Masts

A warehouse forklift must match its environment—not just in lifting power, but also in mast dimensions. Key considerations include:

1. Lift Height: Standard options range from 3 to over 7 meters (10 to 23 feet).

2. Collapsed Height: Important for entering low-clearance areas, such as trailers or containers.

3. Free Lift: Some masts allow forks to rise without increasing overall mast height, ideal for tight spaces.

TDER, a trusted name in the forklifts industry, offers customizable mast solutions tailored to different operational demands—ensuring you get the best forklift for the job.

TDER Forklift Mast Table | |||

Max. Lifting Height | Simplex Mast | Duplex Mast | Thriplex Mast |

3000mm | √ | √ | × |

3300mm | √ | √ | × |

3500mm | √ | √ | × |

4000mm | √ | × | × |

4500mm | √ | × | √ |

4800mm | × | × | √ |

5000mm | √ | × | √ |

5500mm | √ | × | √ |

6000mm | √ | × | √ |

6500mm | × | × | × |

7000mm | × | × | × |

Selecting the Right Forklift Mast

To ensure optimal performance and safety, consider:

1. Ceiling height and obstructions

2. Rack system height and load handling needs

3. Indoor vs. outdoor operation

4. Load type and frequency of lifting

5. Operator's need for vision and flexibility

Today, more businesses are shifting from simply choosing forklifts by load capacity to optimizing entire workflows by specifying the right mast structure. Mast configuration is no longer just a specification—it's a performance lever.

With extensive field experience and engineering expertise, TDER offers tailored mast solutions based on real operating conditions. If your facility involves height restrictions, confined paths, or intensive stacking needs, our team can assist with simulation analysis and professional configuration advice—helping you unlock the full value of every cubic meter in your operation.