Service Hotline:86-0592-5681408 / 86-17346269651

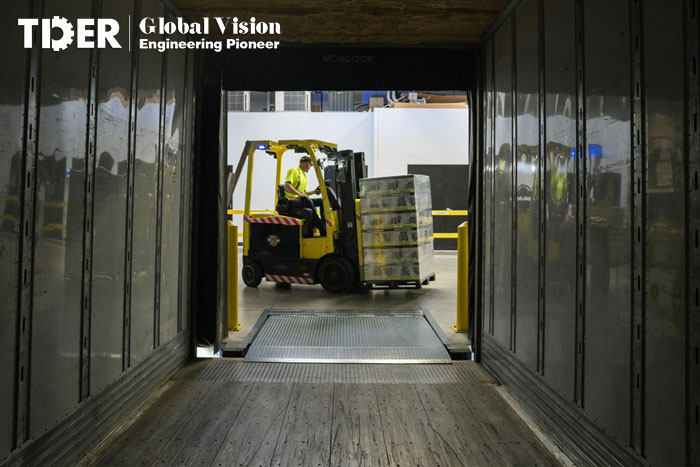

As the 2030 deadline for zero-carbon ports approaches, Europe’s port industry is undergoing profound transformation. In response to increasingly stringent environmental regulations and sustainable development goals, major ports—from Rotterdam to Antwerp, Hamburg to Barcelona—are accelerating their green transition efforts. As the core equipment underpinning port operations, the electrification of forklifts has become a vital component in achieving zero-carbon objectives. Chinese manufacturer TDER, known for its high-reliability, high-safety electric forklift products adaptable to diverse working conditions, is helping European dealers and port operators position themselves early to secure a competitive advantage for the future.

As early as 2017, the European Union set a target to significantly reduce carbon emissions in the transportation sector by 2030. The European Green Deal further outlined the goal of achieving net-zero greenhouse gas emissions by 2050. As critical hubs of international trade, ports are an essential part of the EU’s decarbonization strategy.

Under the Fit for 55 legislative package, the EU mandates a reduction in greenhouse gas emissions of at least 55% compared to 1990 levels by 2030. Ports must not only cut emissions from their operations but also drive green transformation across the entire supply chain, including freight handling, loading and unloading, and warehousing. Some countries have set even more ambitious targets—for example, the Netherlands requires the Port of Rotterdam to achieve zero operational emissions by 2030.

To meet these goals, Europe’s major ports have launched a series of low-carbon initiatives, including the construction of onshore power supply (OPS) systems, alternative ship fuels, and the promotion of new energy vehicles in port zones. The electrification of key equipment such as forklifts, electric tractors, and automated stackers has become an indispensable step in the ports’ green transition.

Industry data shows that a large number of internal combustion forklifts are still in use across European ports, especially in heavy-duty and all-weather operations where diesel-powered forklifts dominate. Achieving zero-carbon operations makes the transition to electric forklifts inevitable.

I. Application Needs of Electric Forklifts in Different Port Scenarios

1. Container Yards: High Load Capacity and All-Weather Operation

In container yards, containers unloaded from ships by gantry cranes or reach stackers are temporarily stored before further handling. Forklifts often operate inside containers or on warehouse floors. Given the large size and heavy weight of containerized cargo, forklifts must have high load capacity and exceptional stability. China’s General Design Code for Seaports also specifies prioritizing electric-driven equipment to minimize pollutants and carbon emissions. Additionally, forklifts must withstand outdoor or semi-outdoor operations year-round, requiring strong power systems, high protection ratings for electronic controls, waterproofing, dustproofing, and rugged pneumatic tires suitable for uneven surfaces.

2. Breakbulk Terminals: Adaptability to Diverse Cargo and Rough Terrain

Breakbulk terminals handle diverse cargo types such as bagged goods, lumber, and petroleum products. Forklifts are needed to move palletized or bundled cargo and assist with oversized cargo handling. The uneven terrain and dispersed operations at breakbulk terminals demand highly adaptable forklifts, often fitted with specialized attachments (e.g., timber clamps, coil handlers). Traditionally, diesel forklifts have dominated this environment due to operational demands, but under the twin carbon goals, electric and hybrid forklifts are gradually being introduced.

3. Cold Chain Logistics Warehouses: Zero Emissions and High Energy Efficiency

Cold storage warehouses maintain temperatures well below freezing year-round, requiring forklifts with zero emissions and no exhaust pollution. Internal combustion forklifts are unsuitable because nitrogen oxides and water vapor emissions can compromise cargo quality. Therefore, only electric or hydrogen-powered forklifts are allowed. Lithium-ion battery forklifts, offering efficient charging and discharging with no emissions, are preferred. Lithium-ion forklifts with specialized insulation can maintain about 95% energy efficiency even at -20°C.

4. Shore Power, New Energy, and Green Investment Trends

According to the 2024 Environmental Report by the European Sea Ports Organisation (ESPO), 58% of European ports are now equipped with onshore power supply (OPS) systems, and 56% offer high-voltage OPS. Additionally, 48% of ports have LNG bunkering facilities, and 44% are participating in hydrogen project pilots. Furthermore, 61% of ports offer differentiated port fee discounts to encourage the use of clean fuels or environmentally friendly ships.

Electrification of port equipment is also gaining momentum. A report by the International Association of Ports and Harbors (IAPH) indicates that introducing electric equipment and building shore power infrastructure are now common decarbonization actions. Even partial electrification—such as forklifts or rubber-tired gantry cranes—can significantly reduce nitrogen oxide (NOₓ) emissions and improve port air quality.

II. TDER Electric Forklifts: Tailor-Made for Zero-Carbon Ports

As a Chinese brand with years of experience in the construction machinery and material handling sectors, TDER leverages its independent R&D and manufacturing capabilities to offer a range of electric forklifts optimized for the high-intensity demands of port operations. Its product lineup—including the K Series economy lithium forklifts, E Series premium lithium forklifts, and lead-acid electric forklifts—has passed EU CE certification, complying with the Machinery Directive (2006/42/EC) and Electromagnetic Compatibility Directive (2014/30/EU), ensuring legal sales and operation within the European market.

1. K Series Economy Lithium Forklifts: For General Port Applications

TDER’s K Series lithium forklifts are designed for general handling tasks within ports, balancing economy with durability:

Robust and Durable: The machine hood is made using integrated sheet metal molding for enhanced strength and sealing, extending service life.

Easy Maintenance: A large-opening hood design concentrates batteries, motors, electrical components, and hydraulic tanks in one area for efficient maintenance.

High Protection Level: IP54-rated protection across the entire vehicle, with high-temperature-resistant wiring, supports safe operation in rain and humid environments.

Comfort and Safety: Equipped with thickened shock-absorbing seats and automatic power cut-off when the operator leaves the seat, improving handling comfort and operational safety.

Efficient Battery System: Uses mature lithium iron phosphate (LiFePO₄) cells, with over 95% charge/discharge efficiency and rapid 1.5–2-hour charging.

Excellent Off-Road Performance: Integrated casting steering axle with strong impact resistance and buffer block design for stable operation on uneven port terrain.

The K Series is particularly suited for container yards, port warehouses, and port logistics distribution centers, offering a reliable low-carbon alternative.

K Series 3.5 Tonne Li-ion Forklift Truck

2. E Series High-Performance Lithium Forklifts: For Heavy-Duty and High-Intensity Operations

For yard operations, heavy cargo handling, and high-frequency usage, TDER’s E Series lithium forklifts are the preferred choice:

Secure Start System: Key ignition + PIN code or card authentication to prevent unauthorized operation.

Enhanced Mast Design: Widened mast improves driver visibility by 20%, with custom-shaped steel enhancing load-bearing capacity.

Extended Battery Life: Lithium battery modules offer 5 years or 10,000 hours warranty with over 80% capacity retention.

Fast Charging and Battery Swap: 1.5–2 hours for full charge; side-extraction chassis design enables quick battery swapping.

Intelligent Hydraulic System: Split hydraulic tank design reduces battery heat load and hydraulic energy consumption.

Higher Energy Efficiency: Direct-drive motor transmission boosts energy efficiency by 30%, improves start-up responsiveness, and extends runtime.

Ultimate Stability: Lowered vehicle center of gravity and automatic cornering speed limits effectively prevent rollover risks.

Enhanced Operator Experience: Full-surround luxury seats with automatic power cut-off when leaving the seat ensure both comfort and safety.

The E Series is specifically engineered for continuous long-hour operations, heavy lifting, and complex road conditions—perfectly aligned with the demands of port operations.

E Series 1.8 Tonne Li-ion Forklift Truck

3. Lead-Acid Electric Forklifts: The Traditional, Reliable Option

TDER also offers mature-performance lead-acid electric forklifts, ideal for budget-conscious port users or stable working environments:

High Safety Standards: Equipped with an OPS system and a BMS battery management system to monitor batteries, motors, and electrical components in real-time.

Efficient Charging: Achieves over 90% charge/discharge efficiency, with 1.5–2-hour fast charging for on-demand energy replenishment.

Optimized Hydraulic System: Full-hydraulic load-sensing steering provides rapid response and easier maneuverability.

The lead-acid series remains highly cost-effective for medium-intensity port storage and handling operations.

4. Full EU CE Certification Across the Product Line

Importantly, all TDER electric forklifts—including the K Series, E Series, and Lead-Acid Series—have passed EU CE certification, complying with the Machinery Directive (2006/42/EC) and the Electromagnetic Compatibility Directive (2014/30/EU). This demonstrates TDER’s strict control over product quality and safety, and eliminates regulatory barriers for European dealers promoting forklifts across various ports.

III. Electric Forklift Deployment Strategy for European Ports

Facing the 2030 zero-carbon mandate, forklift dealers and port operators across Europe are accelerating deployment. TDER provides multiple strategic support options:

1.Phased Equipment Upgrades: Introduce electric forklifts gradually to replace internal combustion units in batches, easing initial capital pressures and achieving step-by-step electrification.

2.Model Selection Based on Operating Conditions: Deploy K Series, E Series, or Lead-Acid Series models flexibly across different areas of the port, optimizing cost and performance balance.

3.Building Green Demonstration Zones: Establish “zero-carbon demonstration areas” within ports using TDER electric forklifts to create successful pilot models for wider rollouts.

4.Strengthening After-Sales and Quick Response Systems: TDER supports dealers in building local spare parts warehouses and technical training systems to ensure fast forklift maintenance, boosting customer satisfaction and loyalty.

5.Expanding New Energy Cooperation: Integrate forklift electrification with port shore power systems, battery swapping stations, and renewable energy projects. Collaborate with major forklift manufacturers like Toyota, TDER, Hyster, and Linde to provide complete new energy solutions and enhance overall competitiveness.

Achieving zero-carbon ports by 2030 is not just a slogan—it’s a profound transformation shaping the future survival and competitiveness of global ports. With tightening regulations, shifting client demands, and the surge of green investments, forklift electrification is now an irreversible trend.

TDER, with its mature and reliable electric forklift lineup, comprehensive CE certifications, and deep expertise in port adaptation, is becoming a crucial partner for European dealers and port operators aiming for a green future.

The countdown has begun—those who act early will secure their place in the logistics map of the zero-carbon era.